What is a Ball Valve?

In hydraulic valves, a rotary ball (a spherical perforated obstruction) stops or starts the flow of fluid. For ball valves to open and close, they are rotated 90° around their axis. It is one of the most commonly used valve types. Ball valves can be used for liquids as well as gases. Because of their long service life and reliable sealing throughout their service life, they are highly popular in the chemical, petrochemical, and oil and gas industries. Vacuum and cryogenic applications can even be performed with ball valves. These valves were developed around 1936 and are among the least expensive valves available in a wide range of sizes. We are the leading valve manufacturer in Zambia.

Due to their cost-effectiveness, ball valves sometimes use control valves, but they do not prefer they do not provide precise control and adjustment.

Applications of Ball Valves

Ball valves have a number of major applications, including

Refineries use ball valves as shut-off valves and isolation valves for tower bottom lines and thermal cracking units; separation lines between gas and oil, gas distribution measuring, metering, and pressure regulation stations, oil loading control stations, pumping and compressor stations, emergency shut-down loops, refineries.

The use of ball valves in chemical and petrochemical complexes includes controlling low differential pressure, reducing emissions, handling highly viscous fluids, and storing abrasive slurries.

Applications of ball valves in the power industry include boiler feedwater control, burner trip valves, steam control, shut-off valves, etc.

Also, read “Which features make roller shutters the first choice of people?”

The use of ball valves in gas and oil production includes subsea isolation and shut-down facilities, oil-head isolation, pipeline surge control, processing separation, storage, transmission, and distribution, and secondary and enhances oil recovery.

In the pulp and paper industry, ball valves use as shut-off valves, digesters, blowers, liquor fillers, lime mud flow controls, dilution water control valves, etc.

Parts of a Ball Valve

The seat of a ball valve is a disc that lies between the ball and the body. In addition to providing the necessary seal, it also supports the ball. Ball valves rotate by a power source that supplies energy to the stem.

Levers and handles use during manual actuation, which controls the operator. Power sources for automatic actuators include electric, pneumatic, and hydraulic. In packing, the media seal around the stem to prevent it from escaping. Contains the stem and packing, the bonnet is part of the ball valve body.

Full-port valves have minimal pressure loss and recovery as the flow passes through them. The flow passes through full-port valves with minimal pressure loss and recovery. In this case, there is no restricting flow, except for some geometric variations at the orifices, since the flow passageway has a diameter similar to the pipe’s inside diameter. Full-port valves have two orifices, one upstream and one downstream, because of the length of the bore through the ball. During the mid-stroke of the valve, the flow moves through the narrowed orifice, creating a pressure drop, and into the larger bore inside the ball where pressure recovers. Once again, the flow moves to the second orifice, where the pressure drops and then recovers. As a result of the dual pressure drops, this two-step process creates lower process velocities, which is important for slurry applications. As a full-port valve moves through a quarter-turn motion, the flow area of the ball’s hole decreases, providing an equal-percentage characteristic with a true circular opening. With the flow passageway shrinking as the valve approaches closure, the sliding action of the ball against the seal creates a scissors-like shearing motion. When slurries close, long fibers or particulates can shear off and separate.

Working on a ball valve

The ball valve is a rotary motion valve. As the stem transfers motion to the ball (Item 03), the ball rotates. The ball valve seats (item 05) rest and support the ball valve ball. By rotating the ball over the valve seats, the bore can open or close, allowing fluid to flow or stop.

If a full-port ball use manual ball valves with normal service, flow continues uninterrupted through the valve with a minimal pressure drop if the ball port openings align with the inlet and outlet ports. Reduced-port balls result in a greater pressure drop. The flow passages of the hand operator are in-line with the flow passages of the body when the hand operator is parallel to the pipeline, allowing full flow through the closure element. Turning the hand operator to the closed position causes the ball’s opening to move perpendicular to the flow stream, while the edges of the port rotate through the seat. Upon reaching the full quarter-turn, the port is completely perpendicular to the flow stream, preventing flow.

Throttling valves experience a double pressure drop through the ball in a midturn position, similar to plug valves. Using a characterizable ball, a specific amount of port opening expos to the flow as the ball rotates from close open through the seat until 100 percent flow achieves at the full-open position.

In the same way as all rotary-action valves, the ball valve strokes in a quarter-turn motion, with 0° as full-closed and 90° as full-open. With a linear actuator design with a transfer case, linear motion can convert to rotary motion, as with a manual handler.

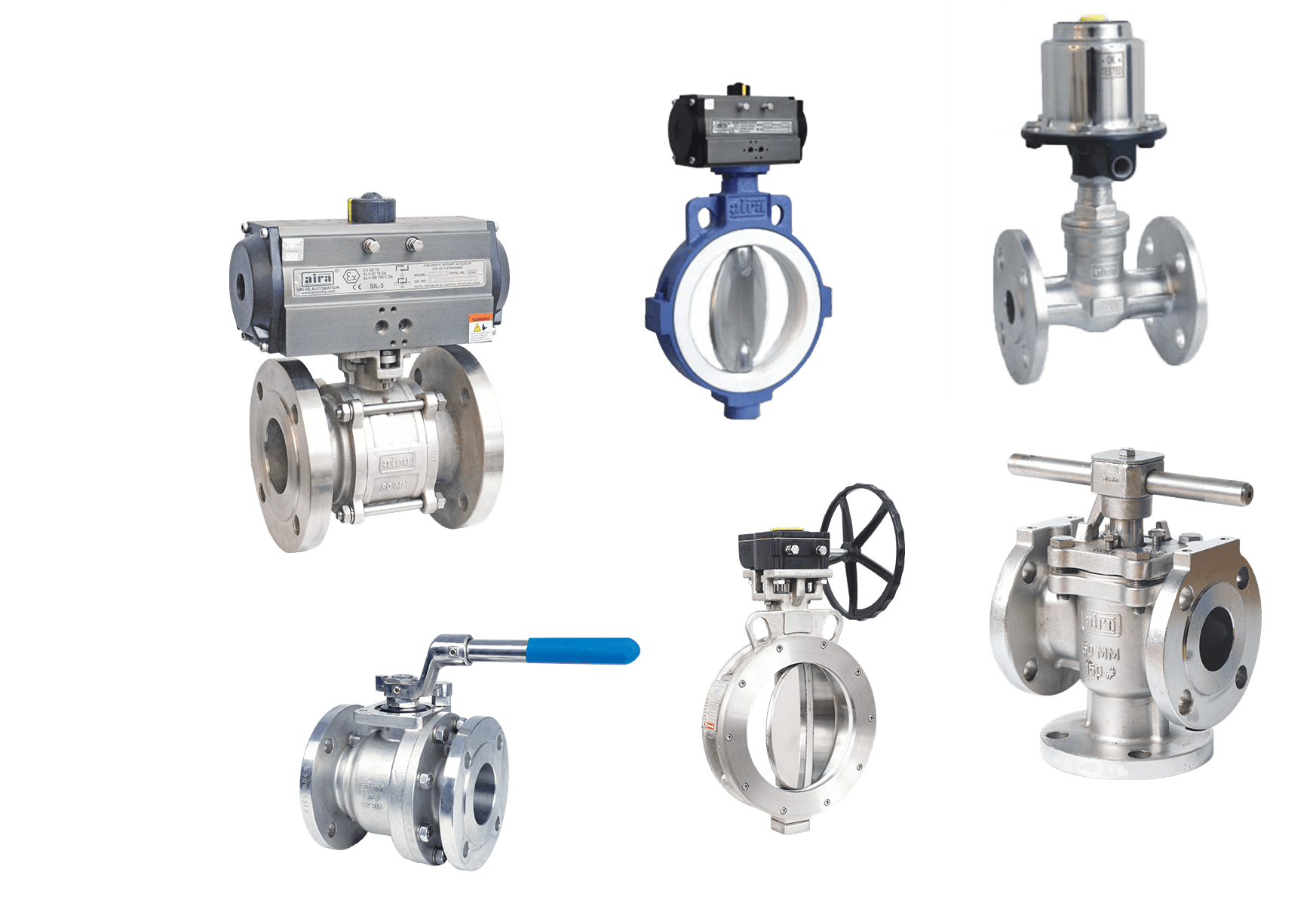

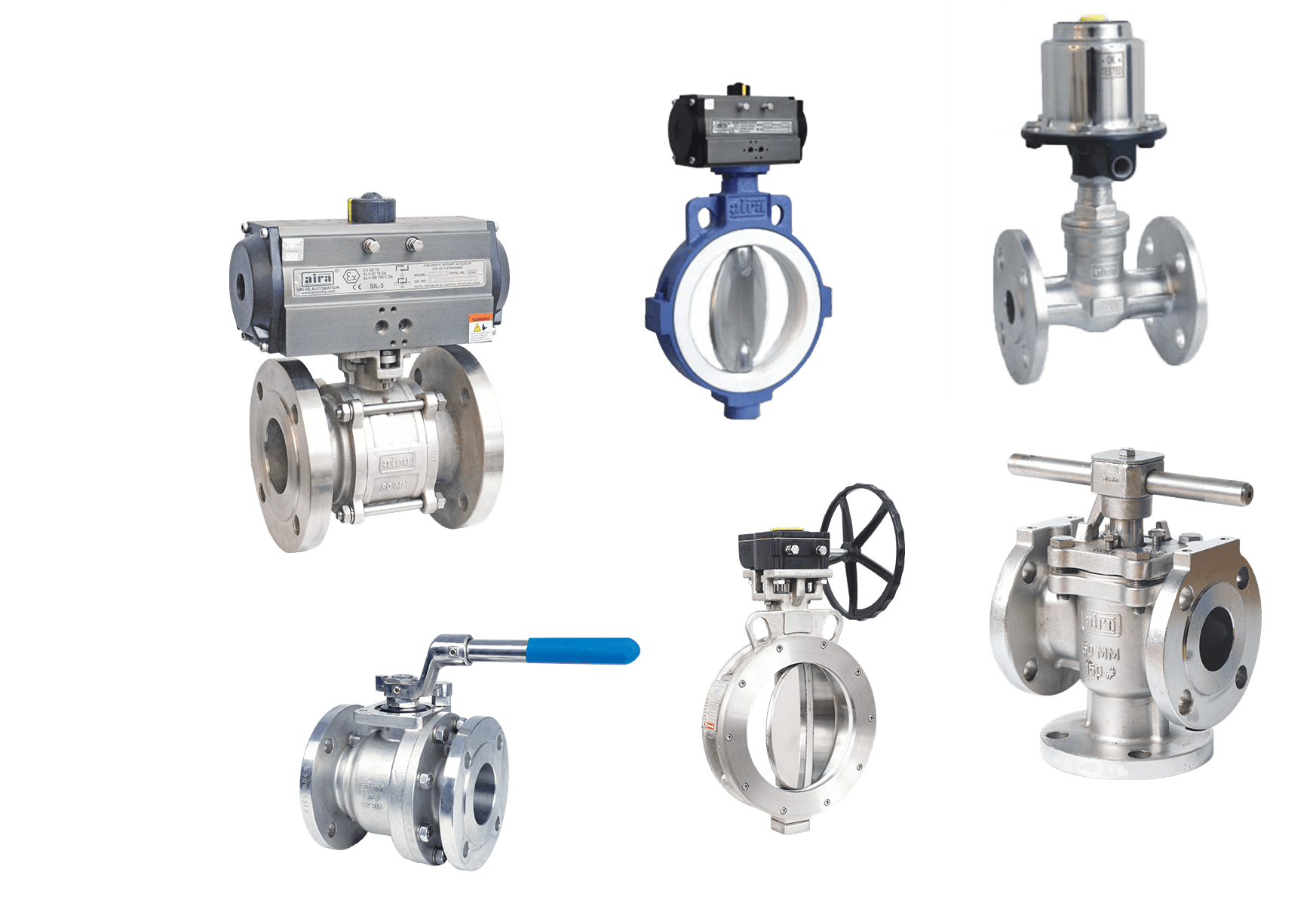

Aira Euro Automation is the leading valve manufacturer in Zambia. We offer various types of industries like ball valves, butterfly valves, control valves, plug valves, pressure reducing valves, and many more.

Ball Valve Types

1. There are two types of ball valves: short pattern and long pattern

There are two types of ball valves, depending on the valves’ end-to-end dimensions. As follows:

Short pattern ball valves have a smaller end-to-end dimension and weigh less than long pattern ball valves. For ease of connection to pipe flanges, long pattern dimensions select during the piping design process. A short-pattern ball valve cannot order after a specific size and flange rating. It is therefore only possible to use long pattern ball valves in these situations.

2. Types of Ball Valves: Soft Seated vs Metal Seated

Generally, soft, non-metal seated ball valves are suitable for most applications. PTFE, NBR, and other thermoplastic materials use in soft seated ball valves. However, abrasive media, high pressure, and high temperatures can severely damage polymeric seals. The 1960s saw the development of metal-seated ball valves as a result of this.

316 SS, Monel, and other metals use the seat material of metal seated ball valves. A metal-seated ball valve’s advantages over its soft-seated counterparts include tight shut-off, no jamming, smooth control, good corrosion and wear resistance, wide temperature range, stability under pressure, etc.